When working in construction, specifically in cement work and concrete form laying, environmental conditions play a vital role in the overall quality of the finished product. Low humidity and excessively warm temperatures can cause unwanted surface cracking to appear in concrete once it dries, potentially causing degradation over time under the right circumstances. These surface imperfections are known as plastic shrinkage cracking and can be minimized or avoided if you take the necessary precautions when mixing and laying fresh concrete.

What Is It?

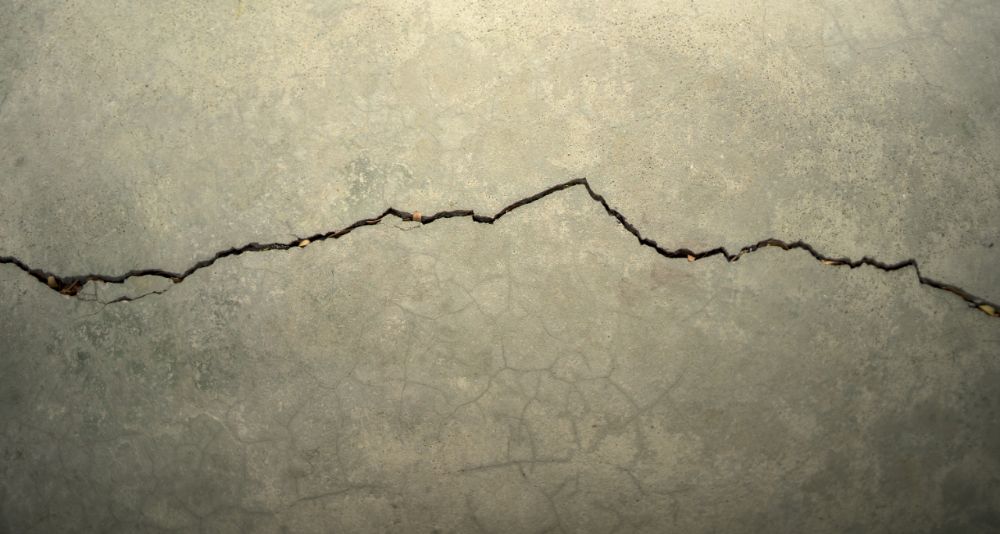

Since concrete has a relatively low tensile strength, cracks form on the surface of it if applied stress exceeds that strength limit. While concrete sets, it is still in its moldable plastic state, which is where the term “plastic” shrinkage cracking comes from. Cracks that form during this stage can be random and may not be completely visible until the next day. Once the cracks are fully developed, they range from 25 millimeters to 2 meters in length and can vary in depth.

What Causes Plastic Shrinkage Cracking?

Plastic shrinkage cracking almost always occurs because the surface dries too quickly before it has time to strengthen. Rapid evaporation of water from the surface of the concrete can allow water particles from its base to displace at the surface and cause cracks. This condition is similar to the cracking that occurs in clay soil when it dries, specifically in environments where there is very little moisture. Other environmental factors that can cause plastic shrinkage cracking are high temperatures and excessively windy conditions.

Prevention

There are steps you can follow to help reduce the likelihood of plastic shrinkage cracking from occurring. Keeping the subgrade and formwork moist before pouring the cement mixture will help the ensure the concrete maintains enough moisture while it dries to prevent cracking. When working in warmer environments, using crushed ice water for your concrete mix can regulate its temperature, so the concrete settles appropriately. Taking a proactive approach to preparing the job site for better wind protection and proper shading can also help minimize any unwanted side effects from the concrete drying too quickly.

Repairing Plastic Shrinkage Cracking

Unfortunately, plastic shrinkage cracking may be hard to spot until the product begins to dry. At this stage, however, it’s not impossible to remedy the situation. If plastic shrinkage cracking is discovered on already hardened concrete, there are proprietary fillers that can be used for cracks two millimeters or broader. While this solution will not hide the cracks altogether, it can ensure the concrete remains durable over time. Still, addressing plastic shrinkage cracking before the product dries is the preferable method of repair. These types of repairs can be done quite quickly by using surface vibrators and a re-work of surface finishing.

Family owned and operated since 1969, Knight’s Companies is a concrete company in Columbia, SC. Knight’s upholds the highest standards in all aspects of the business, and will complete commercial concrete jobs other companies won’t even quote.